How the Athenian School got a new monument sign!

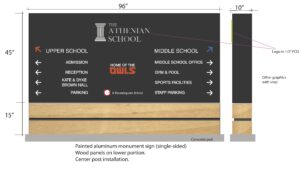

We received a call from a good repeat customer Sequoia Signs & Graphics. They had a customer for a monument sign.Monument concept from sign company

We looked at the drawings and the concepts. These were not detailed enough to build the sign, but they clearly showed us what the customer wanted. We designed the manufacturing drawings and got approval from Sequoia.

In the meantime, Sequoia got the customer’s approval and applied for permits. Sequoia does not do installs, but we both know a strong installer in the area, so the installation would not be a problem. The permits took a while, Once the City approved and issued the permits, we started construction.

Monument signs come in a number of types. In this case we used an Aluminum tubular frame and Aluminum skins. This is a standard construction, We buy the tubes in 20 foot lengths, precession cut these to size and weld the skeletal frame. Inside the frame, there is a feature called a saddle. This is the way the monument fits over the pole that is set into a concrete footer. The frame construction depends on clean and strong welds. We use Aluminum MIG welding and hold a government structural welding certification. Using our expert welders, we got the frame.

We have a CNC router and cut the sides to accurate sizes the exactly fit the frame. We attached these sides and did a small amount of “body work” using Bondo, sanding the entire monument for primer and topcoat painting.

The paint is top quality, we use the industry standard Matthews paint system to get an exact color match. The first coat is a primer and bonds tightly to the aluminum. The next coat is the color matched topcoat. This is a little like automotive paint and PPG (the top car paint company) makes it, but the particles are much larger and the finish is not as flat. These differences make the paint more durable than car paints and should last a lifetime.

The installer dug the hole and placed the steel pipe. The concrete was ordered through a local supplier – the volume was calculated from the hole diameter and depth. Most monuments require engineering. This costs a couple of hundred dollars, and it specified the diameter and depth of the hole, the diameter and wall thickness of the pipe.

We finished the sign with a “wood” finish, but it is not wood. The customer wanted wood, but wood does not wear well over a number of years. There is a synthetic product used for high stress applications and we used this. It insures maximum durability

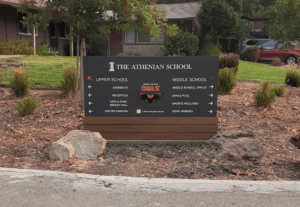

The last step for us was to crate the monument sign and put it on a trailer for transport, not to the customer site of Sequoia, but to the installer. The install loaded the sign directly on the installation truck and to the customer site. It installed flawlessly.

So, what did Sequoia do? They did the most important work. They sold it, They direct the concept and approved the design. They arranged the install and they collected the money. All the construction work and installation was “done by others”.

Do you have a monument sign you want to sell, but lack the manufacturing ability? We can help. 760-730-5118